Wire Harnessing

TA Wire & Harness is a globally recognized leader in the design and manufacturing of custom cable assemblies, wire harnesses, electro-mechanical assemblies, and other interconnect solutions. Our products serve a diverse range of industries, including defense, medical, robotics, UAVs, transportation, industrial equipment, satellite communications, nuclear power, agriculture, forestry, mining, and more. Since our establishment in 1997, we have experienced steady growth, earning a solid reputation for delivering high-quality products, competitive pricing, and outstanding customer service. Our expertise in custom solutions ensures that our clients receive reliable and efficient products tailored to their specific needs, optimizing performance across a variety of applications.

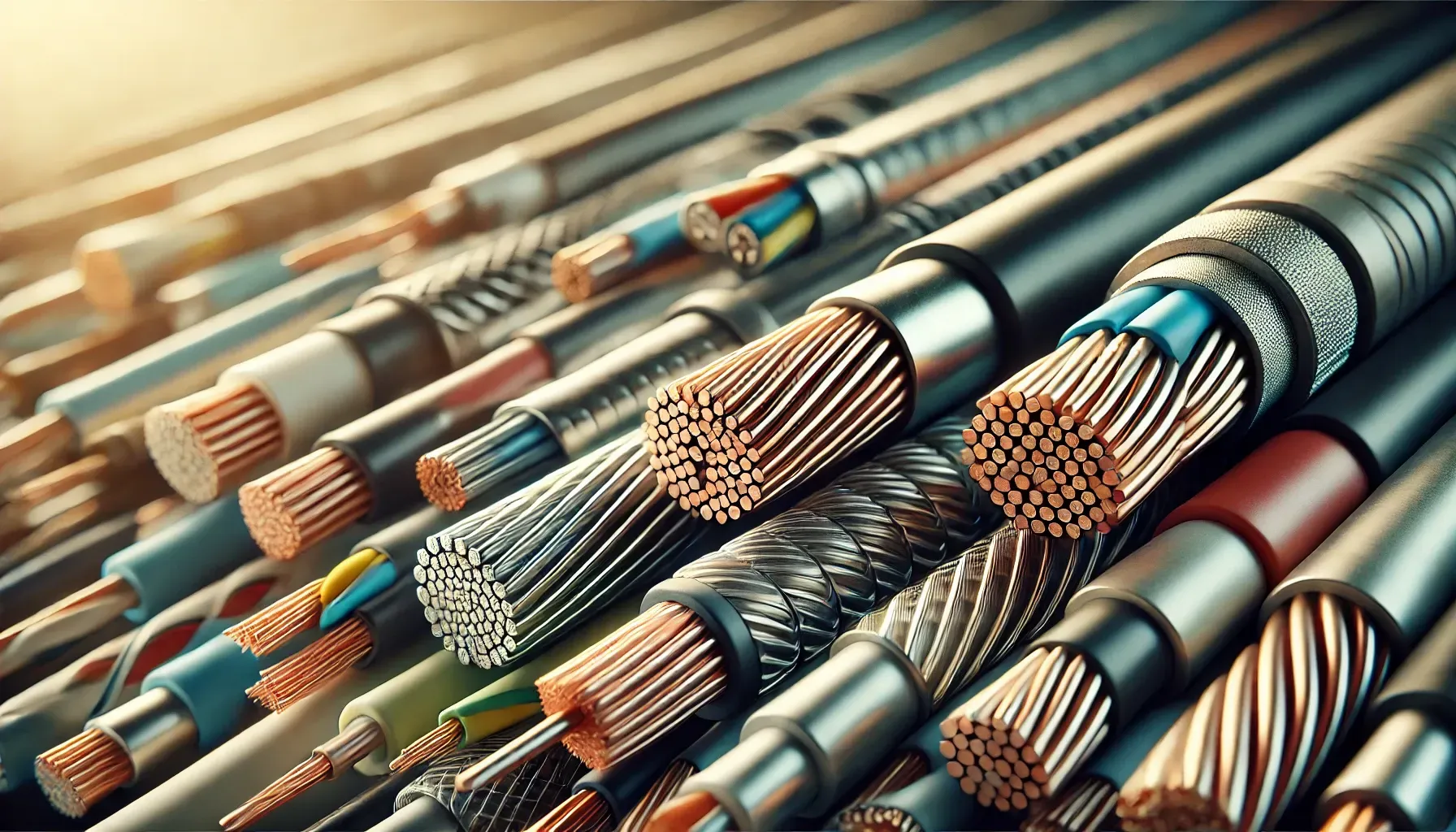

Understanding Cable Assemblies

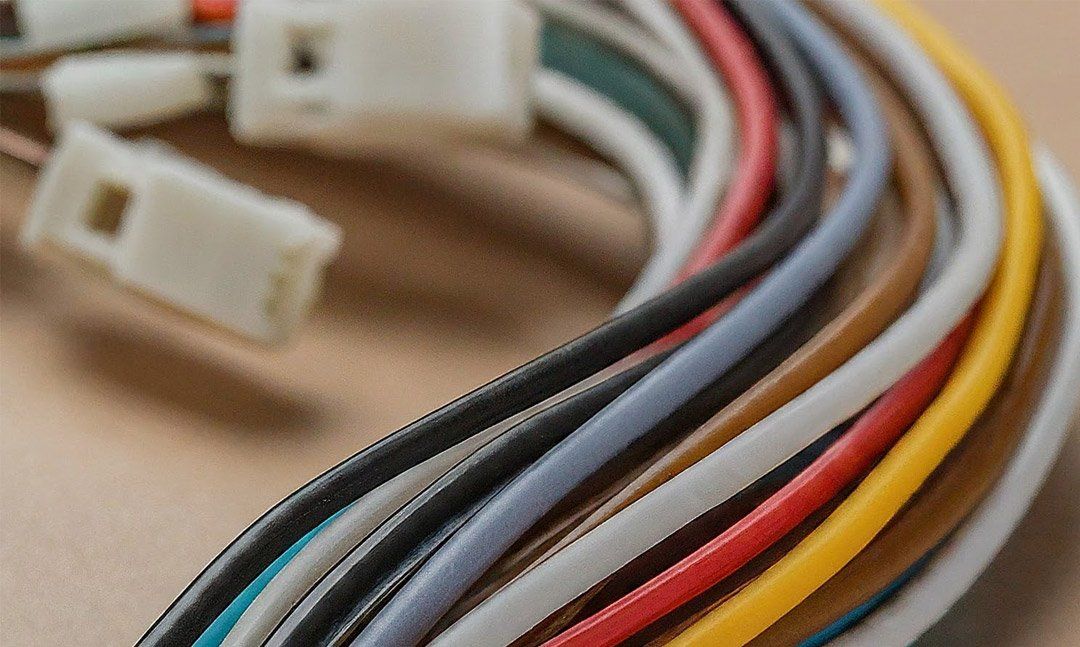

The terms "cable" and "cable assembly" are sometimes used interchangeably, but they have distinct meanings:

- Cable: A combination of drawn metal conductors encased in an insulating layer, arranged in various configurations, and protected by an extruded outer jacket.

- Cable Assembly: A structured assembly that integrates pre-cut cables, terminated at each end per application requirements, ensuring seamless connectivity and integration into different systems.

Customizable Cable Manufacturing

TA Wire & Harness sources cables from both standard off-the-shelf components and specialized manufacturers that create cables to custom specifications. Canadian cable manufacturers, along with divisions of multinational corporations, supply materials designed to meet industry standards and customer demands.

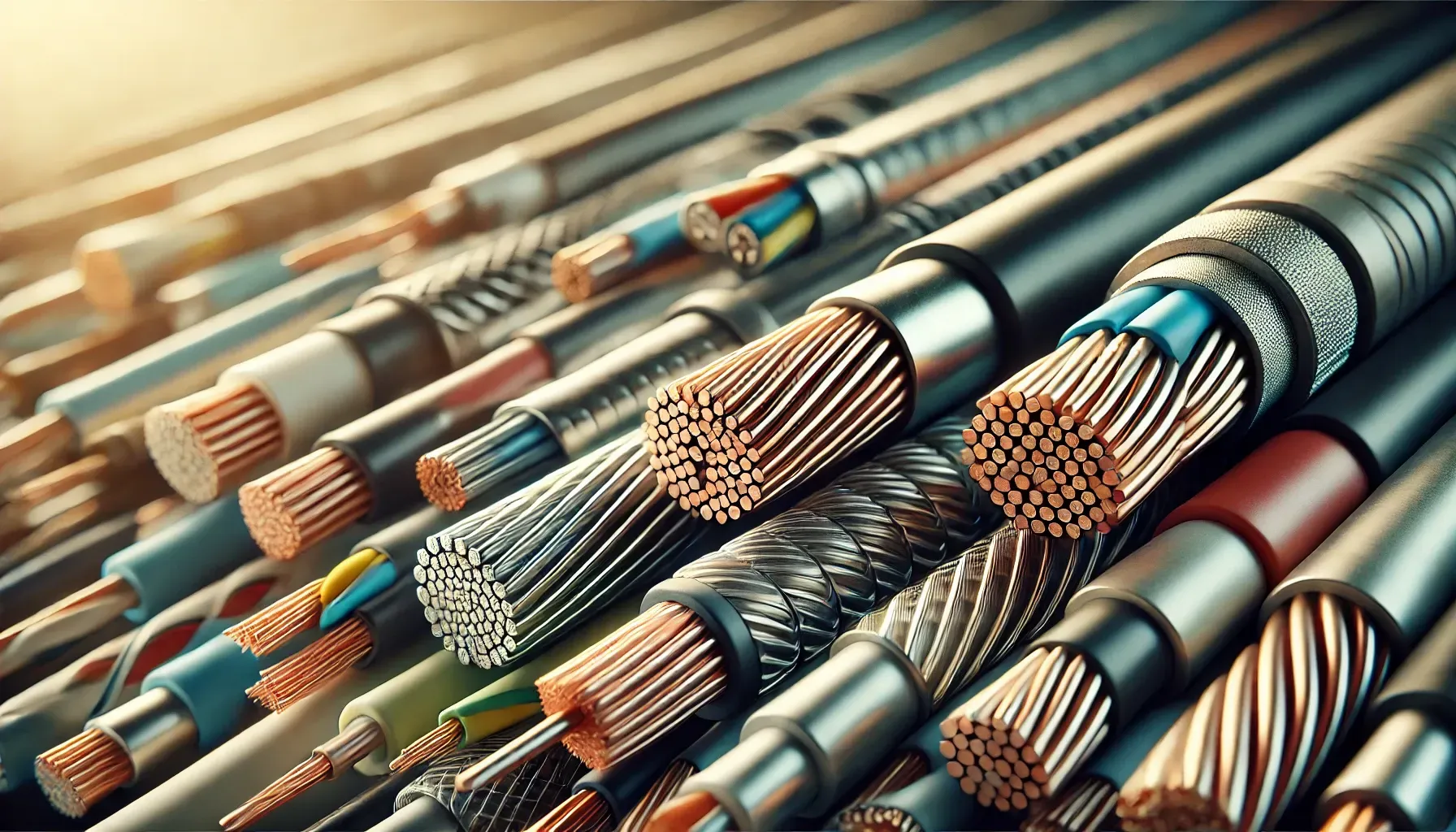

In certain applications, custom cables must be manufactured to precise specifications due to:

- Unique Application Needs: Multi-conductor designs, specific shielding for electromagnetic interference (EMI), and various pairing configurations.

- Environmental Challenges: Resistance to extreme temperatures, sunlight exposure, oil, or water immersion.

- Regulatory Requirements: Compliance with safety standards, voltage ratings, and current-carrying capacities.

Several Canadian manufacturers specialize in producing custom cables in short runs, sometimes as minimal as 100 meters, to meet specialized requirements.

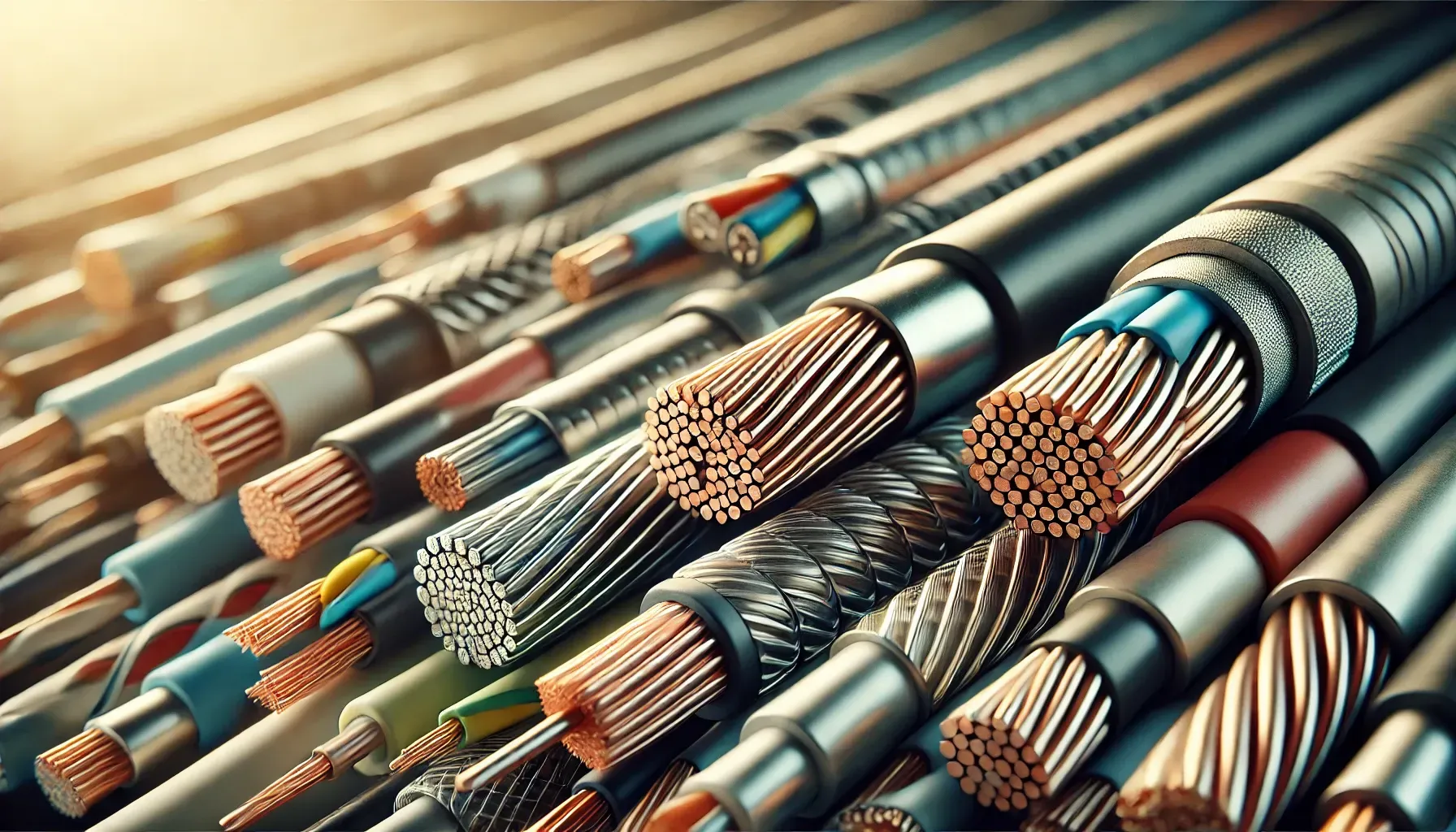

Comprehensive Capabilities in Custom Cable Assemblies

As a premier manufacturer in Canada, TA Wire & Harness collaborates with leading connector companies to produce a vast array of cable assemblies, including:

- Power cable assemblies

- Signal cable assemblies

- Multi-conductor cable assemblies

- Shielded cable assemblies

- Control pigtail assemblies

- RF coaxial cables

- Industrial wiring harnesses

- Antenna cables

- Custom adapters and connectors

- Ribbon and flat cables

- Robotics and flexible harnesses

Each assembly we manufacture is tailored to precise customer specifications. Whether using a standard catalog item or a custom-engineered solution, our rigorous manufacturing processes ensure the highest levels of quality, performance, and durability.

Commitment to Quality and Precision

At TA Wire & Harness, our commitment to excellence is evident in every aspect of our production process:

- Rapid Delivery: We strive to fulfill custom cable assembly orders efficiently to meet customer deadlines.

- Quality Assurance: Our components not only meet but exceed industry regulations, guaranteeing reliability and safety.

- Technical Support: Our engineering team provides expert guidance at every stage, from concept development to final production.

With over 35 years of engineering expertise in design, product development, and manufacturing, we ensure our customers receive maximum return on investment. Our strong industry partnerships and advanced manufacturing capabilities enable businesses to achieve their connectivity objectives with confidence.

Advanced Manufacturing Processes

Our state-of-the-art facilities are equipped with advanced machinery for wire processing, ribbon cable processing, heat shrink processing, and wire marking. These automated and semi-automated systems ensure precision and consistency in every production run. Our stringent quality assurance measures guarantee flawless performance, even in the most demanding environments.

Engineering, Prototyping, and Testing

Custom cable assemblies require meticulous engineering and testing before production. Our design process incorporates:

- Computer-Aided Design (CAD): Engineers construct and simulate virtual models before assembly, ensuring optimal functionality.

- Prototyping: Iterative testing refines designs, optimizes performance, and identifies potential issues before full-scale production.

- Custom Tooling: With an inventory of over 5,000 tools, we develop tailored solutions for connectors, overmolds, junctions, and housings to achieve precision in assembly.

- Comprehensive Testing: We conduct rigorous functionality, safety, and durability tests using both automated and custom testing equipment to meet stringent quality assurance guidelines.

Certifications and Compliance

TA Wire & Harness maintains ISO 9001:2015 certification, demonstrating our commitment to continuous improvement and adherence to global quality standards. Our products undergo extensive inspections to comply with industry regulations, including Underwriters Laboratory (UL) certifications. These certifications guarantee that our cable assemblies meet the highest safety and performance requirements, making them ideal for industries where reliability is paramount.

Applications Across Industries

Our custom cable assemblies are trusted in some of the most challenging environments, including:

- Industrial Controls: Supporting automated systems in utilities, manufacturing plants, and critical infrastructure.

- Military & Defense: Ensuring durability in extreme conditions with enhanced shielding against EMI and radio frequency interference (RFI).

- Telecommunications: Enabling high-speed data transmission in an ever-growing global network.

- Medical Equipment: Providing essential connectivity for life-saving devices, ensuring durability and minimal patient discomfort.

- Consumer Electronics: Powering everyday devices such as smartphones, televisions, and home automation systems.

A Commitment to Excellence

While many cable manufacturers offer standard solutions, TA Wire & Harness takes a more customized approach. We specialize in engineering tailored cable assemblies designed to meet the exact requirements of each application. Our meticulous attention to quality ensures that every product functions flawlessly, even in the most challenging conditions.

If you are searching for a trusted partner to design and manufacture custom cable assemblies and wire harnesses, TA Wire & Harness is here to help. Contact us today to discuss your specific needs, and let us craft a tailored solution that exceeds your expectations.